- Sustainable

- Energy Economy

- Energy Services

What is Round Trip Efficiency?

Energy storage systems function by taking in electricity, storing it, and subsequently returning it to the grid. The round trip efficiency (RTE), also known as AC/AC efficiency, refers to the ratio between the energy supplied to the storage system (measured in MWh) and the energy retrieved from it (also measured in MWh). This efficiency is expressed as a percentage (%).

The round trip efficiency is a crucial factor in determining the effectiveness of storage technology. A higher RTE indicates that there is less energy loss during the storage process, resulting in a more efficient overall system. Grid systems engineers strive for energy storage systems to achieve an 80% RTE whenever feasible, as it signifies a desirable level of efficiency and minimizes energy losses.

What Factors Can Affect the Round Trip Efficiency of an Energy Storage System?

The RTE of an energy storage system can be influenced by various factors, including:

1. Technology: Different storage technologies have varying round-trip efficiencies. For example, hydro storage typically ranges from 65% in older installations to 75-80% in modern deployments, while flywheels have efficiencies of about 80% to 90%. Some battery technologies can have round-trip efficiencies ranging from 75% to 90%.

2. Storage duration: Some technologies may experience leakage or energy loss over long-term storage, which can affect round-trip efficiency. It is important to consider the specific characteristics and limitations of the storage technology when evaluating its efficiency.

3. Age and condition of the system: Older storage systems may have lower round-trip efficiencies compared to newer ones. Factors such as wear and tear, component degradation, and maintenance practices can impact the overall efficiency of the system.

4. Charging and discharging rates: The speed at which energy is charged into and discharged from the storage system can affect its efficiency. Certain technologies may have lower efficiencies at high charging or discharging rates.

5. System design and control: The design and control strategies implemented in the energy storage system can influence its round-trip efficiency. Optimal system design, efficient power electronics, and effective control algorithms can improve the overall efficiency of the system.

6. Temperature: Temperature can have an impact on the performance and efficiency of energy storage systems. Extreme temperatures can affect the efficiency of certain storage technologies, such as batteries, leading to lower round-trip efficiencies.

Considering these factors is crucial when evaluating the round-trip efficiency of an energy storage system, as they can significantly affect its performance and effectiveness in storing and retrieving energy.

Must Read: What is Power Conversion Efficiency?

Elliot is a passionate environmentalist and blogger who has dedicated his life to spreading awareness about conservation, green energy, and renewable energy. With a background in environmental science, he has a deep understanding of the issues facing our planet and is committed to educating others on how they can make a difference.

Related Posts

What is Post-Consumer Recycled (PCR) Content?

What is Heating Seasonal Performance Factor (HSPF)?

What is Annual Fuel Utilization Efficiency (AFUE)?

Save my name, email, and website in this browser for the next time I comment.

Type above and press Enter to search. Press Esc to cancel.

Today in Energy

- Recent articles

- liquid fuels

- natural gas

- electricity

- oil/petroleum

- production/supply

- consumption/demand

- exports/imports

- international

- forecasts/projections

- steo (short-term energy outlook)

Utility-scale batteries and pumped storage return about 80% of the electricity they store

Electric energy storage is becoming more important to the energy industry as the share of intermittent generating technologies, such as wind and solar, in the electricity mix increases. Electric energy storage helps to meet fluctuating demand, which is why it is often paired with intermittent sources. Storage technologies include batteries and pumped-storage hydropower , which capture energy and store it for later use. Storage metrics can help us understand the value of the technology. Round-trip efficiency is the percentage of electricity put into storage that is later retrieved. The higher the round-trip efficiency, the less energy is lost in the storage process. According to data from the U.S. Energy Information Administration (EIA), in 2019, the U.S. utility-scale battery fleet operated with an average monthly round-trip efficiency of 82%, and pumped-storage facilities operated with an average monthly round-trip efficiency of 79%.

EIA’s Power Plant Operations Report provides data on utility-scale energy storage, including the monthly electricity consumption and gross electric generation of energy storage assets, which can be used to calculate round-trip efficiency. The metrics reviewed here use the finalized data from the Power Plant Operations Report for 2019—the most recent year for which a full set of storage data is available.

Pumped-storage facilities are the largest energy storage resource in the United States. The facilities collectively account for 21.9 gigawatts (GW) of capacity and for 92% of the country’s total energy storage capacity as of November 2020.

In recent years, utility-scale battery capacity has grown rapidly as battery costs have decreased. As batteries have been increasingly paired with renewables , they have become the second-largest source of electricity storage. As of November 20, 2020, utility-scale battery capacity had 1.4 GW of operational capacity. Another 4.0 GW of battery capacity is scheduled to come online in 2021, according to EIA’s Preliminary Electric Generator Inventory .

Although battery storage has slightly higher round-trip efficiency than pumped storage, pumped-storage facilities typically operate at utilization factors that are currently twice as high as batteries. Increasing durations among battery applications could shift battery operations toward services that reward longer output periods. For example, in 2015, the weighted average battery duration was a little more than 46 minutes, but by 2019, weighted average battery durations had doubled to 1.5 hours. The role of batteries and their capability to provide high levels of round-trip efficiency may become more important as batteries continue to be deployed and as the intermittent renewables share of the electricity mix grows.

Tags: storage , electricity

This is the UK domain, to see the EU or other regions, please click below

- Visit the GivEnergy cloud

- All in One – battery plus inverter

- AC coupled inverter

- Hybrid inverter

- Battery storage

- Full energy ecosystem overview

- Start your journey

- Commercial All in One

- Power conversion system (PCS)

- Battery packs

- Commercial battery rack

- SME battery system

- Battery storage container

Energy management software

- GivEnergy app

- GivEnergy portal

- GivEngineer – installer commissioning app

- Home battery storage

- Commercial battery storage

- Sustainable construction projects

- Social housing project

- Wholesalers

- Energy suppliers – E.ON partner

- Energy suppliers – Octopus

- Energy aggregators

- Solar industry – Open Solar

- Solar industry – Easy PV

- Giv-Gallery

- Case studies

- Support hall of fame

- Why choose GivEnergy?

- Refer a friend

- Find a distributor

- Knowledge base

- Community forum

Documentation

- Resource hub

- Domestic product brochure 2024

- Commercial product brochure 2024

- GivEnergy API

- Server status

- View all posts

3 biggest threats to our electricity supply (& how battery...

[PRODUCT UPDATE] We’re opening the beta on parallel All in...

Are GivEnergy batteries compatible with third-party kit?

- FIND AN INSTALLER

- Home-owners

- January 30, 2024

- Blog , Commercial battery storage , Domestic battery storage , Explain like I’m 5

What is round trip efficiency in battery storage?

Round trip efficiency (RTE) is a measure of how efficiently a battery can store and discharge energy. Find out why it’s crucial in the world of BESS.

Terminology in the world of battery storage can seem daunting to the average Joe.

Luckily, we’re here to help.

Round trip efficiency (RTE) is something you may have come across in relation to batteries.

In a nutshell, RTE measures how efficiently a battery can store and discharge energy.

How is RTE calculated? Why are there no batteries with 100% RTE? How has RTE in storage batteries improved in recent years?

Read on to find the answers to these questions.

How to calculate the RTE of a battery?

The RTE of a battery can be calculated as a percentage using a simple formula shown below:

Energy output ÷ energy input x 100 = RTE

Let’s demonstrate what this means in practical terms with an example.

Mrs Jones installs a storage battery for her home . As she and her family typically use 10 kWh of electricity per day, she opts for a 10 kWh storage battery.

As someone who is both eco-conscious and has an above-average income, Mrs Jones installs both solar panels and a wind turbine to power her battery storage system. This means she can charge her 10 kWh battery from renewable sources.

However, Mrs Jones soon realises that she isn’t getting 10 kWh per day from her storage battery.

In reality, she gets 8 kWh per day. That’s because her 10 kWh battery has 80% round trip efficiency.

If she had opted for a 10 kWh battery with 90% round trip efficiency, she would get… yep… 9 kWh per day.

For her remaining 2 kWh per day of electricity needs, she draws energy from the grid.

Why do batteries lose energy?

Unfortunately, batteries always lose a small amount of energy during operation.

This is usually because of heat loss, self-discharge, high internal cell resistance or other factors.

Are there any batteries with 100% RTE?

You can think of it like this: if anyone ever tries to sell you a 100% RTE battery, run a mile because they’re almost certainly lying.

What is the RTE of a typical battery?

RTE varies among different types of storage batteries .

For older battery systems, 80% round trip efficiency would have been considered a good standard. Some evidence suggests the typical lithium-ion battery – a popular choice for modern battery energy storage systems and electric vehicles – has round trip efficiency of around 83%.

GivEnergy’s own batteries – using LiFePO4 (lithium iron phosphate) – have achieved 93% round trip efficiency .

RTE – not to be ignored

Grid-level battery storage is becoming increasingly common to accommodate the growth in renewables, especially solar and wind.

Round trip efficiency is a factor that decision-makers need to take into account when assessing the overall efficiency of an energy storage system.

And it’s something YOU also need to bear in mind when installing your own battery storage system for your home or business.

Remember: 100% round trip efficiency is a lie! However, 93% round trip efficiency with a GivEnergy battery using LiFePO4 technology is not a lie.

Looking to play your part in the energy storage revolution? Get started by finding an approved GivEnergy installer today.

Further reading

- Explain like I’m 5: depth of discharge

- LiFePO4 battery: what is it & why is it best for BESS?

- The superior choice: embracing LiFePO4 batteries over NMC technology

Quick Links

Getting started with...

Product images used are for illustrative purposes. The finished setup will vary from installation to installation, and will include all your needed cable connections, metering, any (outdoor) canopies, etc.

Performance Analysis of Lithium-Ion Battery Considering Round Trip Efficiency

Ieee account.

- Change Username/Password

- Update Address

Purchase Details

- Payment Options

- Order History

- View Purchased Documents

Profile Information

- Communications Preferences

- Profession and Education

- Technical Interests

- US & Canada: +1 800 678 4333

- Worldwide: +1 732 981 0060

- Contact & Support

- About IEEE Xplore

- Accessibility

- Terms of Use

- Nondiscrimination Policy

- Privacy & Opting Out of Cookies

A not-for-profit organization, IEEE is the world's largest technical professional organization dedicated to advancing technology for the benefit of humanity. © Copyright 2024 IEEE - All rights reserved. Use of this web site signifies your agreement to the terms and conditions.

Empowering Innovations: The Bright Future of Round Trip Efficiency of Battery

Round Trip Efficiency of Battery

The concept of round trip efficiency of battery is pivotal in energy storage technologies. This section will provide an extensive introduction to what round trip efficiency means in the context of batteries.

We'll explore its importance in various applications, ranging from small-scale electronics to large-scale energy systems.

Understanding the round trip efficiency of battery is essential for assessing the performance and sustainability of these energy storage devices.

The Science Behind Round Trip Efficiency

Delving deeper into the technicalities, this part will explain how the round trip efficiency of battery is determined. It will cover the fundamental principles of battery operation, including charge and discharge cycles, energy losses during these cycles, and how they affect overall efficiency. Factors like temperature, charge rate, and battery age, which significantly impact round trip efficiency, will be discussed in detail.

Components Affecting Round Trip Efficiency

In this subsection, we will explore the various components of batteries, such as electrodes, electrolytes, separators, and casings, and how each contributes to or detracts from the round trip efficiency. The material composition of these components, their engineering, and how they interact with each other play a critical role in the efficiency of the battery.

The Role of Battery Design

This part will discuss how the physical and chemical design of a battery influences its round trip efficiency. Topics like battery size, shape, internal architecture, and the arrangement of cells within a battery pack will be covered. The section will also explore how innovative design strategies are being employed to enhance efficiency.

Types of Batteries and Their Round Trip Efficiency

This section will provide a comparative analysis of different battery types, such as lithium-ion, lead-acid, and nickel-metal hydride, focusing on their round trip efficiencies. Each battery type's unique characteristics, advantages, and limitations in terms of efficiency will be discussed.

Lithium-Ion Batteries and Efficiency

Focusing on lithium-ion batteries, this subsection will delve into why they are widely regarded for their high round trip efficiency. We will examine the factors that contribute to this efficiency and the challenges that still exist. The latest advancements in lithium-ion technology aimed at improving efficiency will also be highlighted.

Other Battery Technologies

This part will look at alternative battery technologies, comparing their round trip efficiencies with that of lithium-ion batteries. It will cover emerging technologies like solid-state batteries, flow batteries, and others, discussing their potential to rival or surpass the efficiency of traditional battery types

Improving the Round Trip Efficiency of Battery

This section will explore the various strategies and technological advancements aimed at enhancing the round trip efficiency of battery. It will cover research and development efforts in new materials, battery chemistry, and manufacturing techniques. Discussion will include how these advancements could potentially increase efficiency, reduce costs, and extend the life of batteries.

Innovations in Battery Materials

Delving into the realm of materials science, this subsection will explore new and innovative materials being developed to increase the round trip efficiency of battery. This includes advancements in electrode materials, electrolyte formulations, and separator technologies. We'll look at how these new materials can reduce energy losses during charging and discharging, thereby improving overall efficiency.

The Future of Battery Efficiency

In this part, we will explore the cutting-edge research and future directions aimed at pushing the boundaries of round trip efficiency in battery technology. This will include a discussion on potential breakthroughs, the challenges researchers face, and the implications these advancements could have on the global energy landscape.

Applications and Importance of High Round Trip Efficiency

Discussing the wide range of applications where high round trip efficiency in batteries is critical, this section will cover areas like electric vehicles, renewable energy storage, grid management, and consumer electronics. We'll explore how improvements in battery efficiency can impact these fields, leading to more sustainable and efficient energy usage.

Impact on Electric Vehicles

Focusing on electric vehicles (EVs), this subsection will discuss how the round trip efficiency of battery affects the performance, range, and cost-effectiveness of EVs. We'll explore current challenges, the importance of efficiency improvements in the context of EV adoption, and how advancements could shape the future of transportation.

Renewable Energy Storage Systems

In this part, the role of battery efficiency in the effectiveness and viability of renewable energy storage systems will be examined. We'll discuss how higher round trip efficiency can enhance the storage and release of energy from sources like solar and wind, making renewable energy more reliable and accessible.

Battery Round Trip Efficiency Definition: Understanding the Concept

The definition of battery round trip efficiency is a fundamental concept in the realm of battery technology and energy storage. This section aims to elucidate the battery round trip efficiency definition and its relevance in practical applications.

Exploring the Battery Round Trip Efficiency Definition

Battery round trip efficiency is defined as the ratio of the energy output of a battery to the energy input required to recharge it. This definition provides a quantitative measure of how effectively a battery stores and then releases the energy put into it. It's a critical parameter for evaluating the performance of a battery, as it directly influences the efficiency and cost-effectiveness of the battery in its practical application.

Implications of Battery Round Trip Efficiency in Energy Systems

Understanding the battery round trip efficiency definition is vital for anyone involved in the design, manufacture, or use of battery systems. This efficiency metric is particularly important in applications where energy conservation and efficiency are paramount, such as in electric vehicles, renewable energy systems, and portable electronic devices. A higher round trip efficiency means more of the stored energy is available for use, which is crucial for the overall efficiency and sustainability of these systems.

Environmental Impact of Battery Efficiency

This new section will explore the environmental implications of the round trip efficiency of battery. It will discuss how increased efficiency can lead to reduced energy waste and lower carbon footprints. This part will also cover the lifecycle of batteries, including manufacturing and recycling processes, and how efficiency plays a role in minimizing environmental impact.

Economic Aspects of Battery Efficiency

In this section, we'll delve into the economic aspects of round trip efficiency in batteries. It will cover how higher efficiency can lead to cost savings for consumers and businesses, and its impact on the overall economy. This part will also discuss the investment in research and development for more efficient batteries and how this drives innovation in the battery industry.

Safety and Reliability Concerns

This part will address how the round trip efficiency of battery relates to their safety and reliability. We'll explore the challenges that arise when trying to balance high efficiency with safety, especially in high-demand applications like electric vehicles and energy storage systems. This section will also discuss the measures taken to ensure that efficiency improvements do not compromise the safety and longevity of batteries.

Regulatory and Policy Frameworks

This new section will examine the role of regulatory and policy frameworks in shaping the development and adoption of efficient battery technologies. It will cover current regulations and standards related to battery efficiency, and how these policies impact the industry. Additionally, this part will discuss potential future policies that could encourage or mandate improvements in battery efficiency.

BatteryRound Trip Efficiency Calculation: Methods and Importance

The calculation of battery round trip efficiency is a critical aspect in assessing the performance of battery systems. This section delves into the methodologies and significance of accurately performing batteryround trip efficiency calculation.

Understanding the Basics of Battery Round Trip Efficiency Calculation

To begin with, battery round trip efficiency calculation involves determining the ratio of the energy outputted by the battery to the energy inputted into it during charging. This calculation is crucial for understanding how much energy is lost in the process of charging and discharging a battery. These energy losses typically occur due to factors like internal resistance, heat generation, and the inefficiencies in the battery's chemical processes.

Step-by-Step Process of Battery Round Trip Efficiency Calculation

To calculate battery round trip efficiency, one must first measure the amount of energy inputted into the battery during the charging process. This is typically done in watt-hours (Wh) or kilowatt-hours (kWh). Following this, the energy outputted by the battery during discharge is measured. The round trip efficiency is then calculated by dividing the energy outputted by the energy inputted and multiplying the result by 100 to obtain a percentage. A higher percentage indicates a more efficient battery with less energy loss.

The Significance of Accurate Calculation

Accurate battery round trip efficiency calculation is crucial for several reasons. Firstly, it allows for the comparison of different battery technologies on a uniform basis, aiding in the selection of the most efficient and suitable battery for a specific application. Secondly, understanding the efficiency of a battery helps in estimating its operational costs and its impact on the overall efficiency of the system it powers, such as an electric vehicle or a renewable energy storage system.

Battery Storage Round Trip Efficiency: Key Aspects and Evaluation

The concept of battery storage round trip efficiency is crucial in the context of energy storage systems. This section focuses on defining and understanding the nuances of battery storage round trip efficiency and its impact on energy storage solutions.

Defining Battery Storage Round Trip Efficiency

Battery storage round trip efficiency is a measure that indicates how efficiently a battery can store and then release the energy it has been charged with. This efficiency is calculated by comparing the amount of energy input into the battery during charging to the amount of usable energy output during discharge. A higher battery storage round trip efficiency signifies that a larger portion of the input energy is available for use, making the battery more effective and economical for energy storage purposes.

Importance of Battery Storage Round Trip Efficiency in Energy Systems

In the field of energy storage, especially in systems like grid storage or electric vehicles, battery storage round trip efficiency plays a pivotal role. It directly affects the viability and performance of the storage system. High-efficiency levels mean more energy is available for use from each charging cycle, which is crucial for the overall energy efficiency and operational cost of the system. As such, battery storage round trip efficiency is a key parameter in the selection and design of battery systems for various applications.

Round Trip Efficiency Battery Storage: A Brief Overview

The term roundtrip efficiency in battery storage is a vital metric in the energy sector. This section provides a succinct overview of what round trip efficiency battery storage entails and its significance.

Understanding RoundTrip Efficiency Battery Storage

Round trip efficiency in battery storage refers to the measure of how effectively a battery can store and then return the energy that is put into it. It is a crucial indicator of a battery's performance, affecting the viability and efficiency of energy storage systems. This efficiency is especially important in applications where energy conservation and effective storage are key, such as in renewable energy systems and electric vehicles.

The Role of Round Trip Efficiency in Battery Storage Systems

The significance of roundtrip efficiency battery storage cannot be overstated. It directly influences how much stored energy is actually usable, impacting the overall effectiveness and cost-efficiency of the storage system. High round trip efficiency battery storage means more energy is available for use, reducing waste and improving the sustainability of the system.

Round Trip Efficiency of Battery Formula: Essential Calculation

The round trip efficiency of battery formula is a fundamental equation in battery technology. This section is dedicated to explaining the round trip efficiency of battery formula and its application in measuring battery performance.

The Basic RoundTrip Efficiency of Battery Formula

At its core, the roundtrip efficiency of battery formula involves a simple calculation: dividing the energy output of the battery (measured in watt-hours or kilowatt-hours) by the energy input required to charge the battery, and then multiplying by 100 to express it as a percentage. This formula is critical for determining how much energy a battery can effectively use out of the total energy it consumes during the charging process.

Practical Applications of the Formula

In practical terms, the round trip efficiency of battery formula is used extensively by engineers and technicians to assess the performance of different types of batteries. This formula helps in comparing the efficiency of various battery technologies and designs, playing a crucial role in battery research and development. A higher percentage obtained from this formula indicates a more efficient battery, with less energy lost during charging and discharging cycles.

The round trip efficiency of battery formula is not just a theoretical tool; it has significant practical implications in the development and selection of batteries for various applications, from small electronics to large-scale energy storage systems.

Tesla Battery Round Trip Efficiency: Insights into Performance

Tesla battery round trip efficiency is a key metric that highlights the effectiveness of Tesla's battery technology. This section aims to shed light on the specifics of Tesla battery round trip efficiency and its implications.

Understanding Tesla Battery Round Trip Efficiency

Tesla battery round trip efficiency refers to the efficiency with which Tesla's batteries can store and then release energy. This efficiency is a critical aspect of Tesla's battery technology, reflecting how much energy is retained and available for use after charging. The higher the round trip efficiency, the more effective the battery is at minimizing energy losses during charge and discharge cycles.

Significance of Tesla Battery Round Trip Efficiency in Electric Vehicles

Tesla battery round trip efficiency is particularly important in the context of their electric vehicles (EVs). High round trip efficiency means that more of the energy stored in the vehicle's battery is available for driving, enhancing the vehicle's range and overall performance. Tesla's focus on optimizing battery round trip efficiency has been a significant factor in their EVs' success, as it directly impacts driving range, charging times, and the overall user experience.

Frequently Asked Questions (FAQs) About Battery Efficiency

What is Round Trip Efficiency of Battery?

Round trip efficiency of a battery refers to the measure of how effectively a battery can store and then release the energy that is put into it during charging. It is calculated by dividing the energy output during discharge by the energy input during charging, then multiplying by 100 to get a percentage. A higher value indicates that the battery is more efficient, losing less energy in the process of charging and discharging.

How Does Temperature Affect Battery Efficiency?

Temperature can significantly impact the efficiency of a battery. Extreme temperatures, both hot and cold, can affect the chemical reactions within a battery, thereby impacting its ability to store and release energy efficiently. Typically, high temperatures can accelerate degradation, while low temperatures can reduce the battery's effective capacity.

Can the Round Trip Efficiency of a Battery Improve Over Time?

Generally, the round trip efficiency of a battery decreases over time as the battery undergoes wear and tear from repeated charging and discharging cycles. However, advancements in battery technology, materials, and management systems can lead to improvements in newer batteries. Ongoing research is focused on developing batteries with longer lifespans and better efficiency retention over time.

What Factors Influence the Round Trip Efficiency of Electric Vehicle Batteries?

Several factors influence the round trip efficiency of electric vehicle (EV) batteries. These include the battery's chemical composition, design, the efficiency of the battery management system, and operational conditions such as temperature and charging habits. Additionally, the way the vehicle is driven and the efficiency of other vehicle systems can also impact the overall round trip efficiency of the battery.

Conclusion: The Future of Round Trip Efficiency in Battery

This concluding section will summarize the critical importance of round trip efficiency in batteries, reflecting on the discussed topics. It will envision the future of battery technology with a focus on efficiency, considering the potential impacts on various industries, the environment, and society at large.

Round Trip Efficiency

Energy Storage System Efficiency

Related Posts

Is ceramic heater energy efficient, xiaomi electric vehicle: embrace superior safety and extraordinary efficiency, carbon capture and storage india: essential strategies for environmental excellence, best energy-efficient light bulbs 2024.

Type above and press Enter to search. Press Esc to cancel.

Sign In or Register

Welcome back.

Login to your account below.

HOMER Pro 3.15

- Zoom Window Out

- Larger Text | Smaller Text

- Hide Page Header

- Show Expanding Text

- Printable Version

- Save Permalink URL

The battery round-trip efficiency is the round trip DC-to-storage-to-DC energy efficiency of the storage bank, or the fraction of energy put into the storage that can be retrieved. Typically it is about 80%. HOMER assumes the storage charge efficiency and the storage discharge efficiency are both equal to the square root of the round-trip efficiency.

Battery Charge Efficiency

Battery Discharge Efficiency

- POWER Plant ID

- POWER Events

- Connected Plant

- Distributed Energy

- International

- COVID-19 Coverage

- Carbon Capture

- Climate change

- Cybersecurity

- Distributed Power

- Electric Vehicles

- Energy Storage

- Environmental

- Instrumentation & Controls

- Legal & Regulatory

- Legislative

- Ocean/Marine

- Physical security

- Plant Design

- Power Demand

- Research and Development

- Supply Chains

- Tidal Power

- Waste to Energy

- About POWER

- Privacy Policy

- Cookie Settings

- Diversity, Equity, Inclusion & Belonging

- Accessibility Statement

Don’t Neglect Round-Trip Efficiency and Cost of Charging When Considering Levelized Cost of Storage

The world is moving toward renewable sources for electricity generation in an attempt to reduce fossil-fuel reliance. But wind and solar can’t provide a consistent flow of power 24/7, and grid operators have realized that new electricity generation needs to be paired with storage to manage periods with no sun or wind.

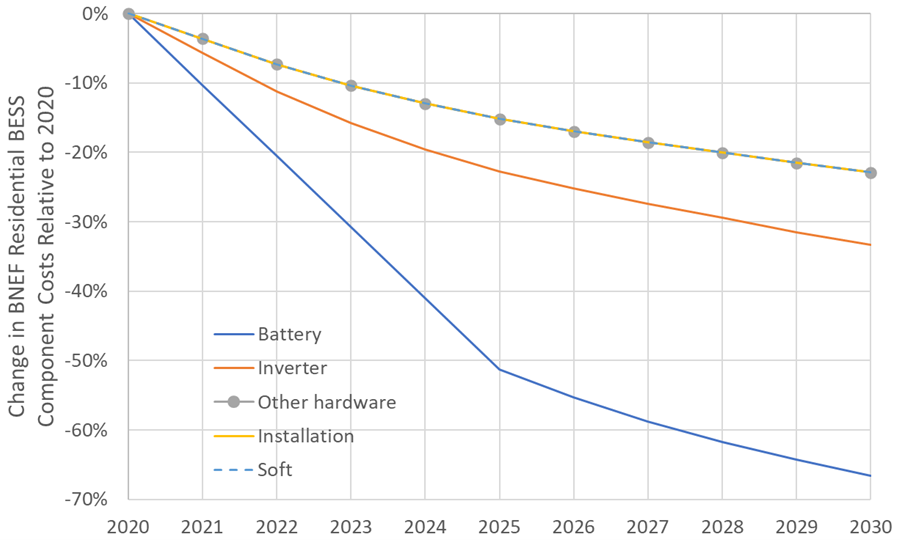

The decreasing cost of lithium-ion batteries has made battery energy storage systems (BESS) more affordable; however, the cost of battery storage systems represents only 20%-25% of any project’s lifetime cost. Power equipment, land, site work, cabling, project design and management, grid integration, transportation, and other related up-front costs represent another 25%.

So, what makes up the other ~50%? Operations and maintenance, otherwise known as O&M, represent a few percentage points. O&M generally includes expenses associated with maintaining, repairing, and operating energy storage systems over their lifespan. The rest comes from the cost of electricity to charge the system, which is significantly affected by the system’s overall round-trip efficiency (RTE).

Why RTE and Cost of Energy Matter

Levelized cost of storage (LCOS) is a metric used to determine the cost per unit of energy discharged from an energy storage system. The calculation is usually expressed in dollars per megawatt hour (MWh) and includes initial costs plus operating costs divided by the energy discharged over the asset’s service life.

There are dozens of potential variables that may be used to determine the true levelized cost of storage, and different vendors will add, omit, or adjust different ones to put their products in the best light. This is why it’s so important to understand the role of RTE and cost of energy in a storage system, because they often have the biggest impact. These are also components that vendors with low-RTE technologies will most often discount (or omit altogether).

Round-trip efficiency is a measure of the amount of energy put into a system compared to the amount dispatched, and is expressed as a percentage. A system with a high RTE (75%+) is able to dispatch most of the energy fed into it. A low RTE indicates that the system loses a considerable amount of energy, often to heat arising from irreversible side reactions or high internal cell resistance. Many long-duration energy storage systems have RTEs below 50%, creating a significant amount of energy waste.

For example, lithium-ion batteries generally have RTEs of 90%+. In contrast, lead-acid batteries have lower RTEs of around 70%, meaning that approximately 30% of charge energy is lost. RTEs for flow batteries can range from 50%–75%, while metal-air batteries could have RTEs as low as 40%.

If the electricity used to charge low-RTE batteries was free, efficiency might not matter much. But electricity always comes with a cost. Some might argue that during periods where supply exceeds demand, renewables could be used to charge batteries when they would otherwise be curtailed. There’s a logic to that, but curtailment periods can’t always be predicted.

Even if you’re using electricity that would otherwise be curtailed, you have to assign a monetary value. If a turbine is spinning or a solar panel is generating electricity and a battery system is storing that electricity, every component in the system is subject to normal wear and tear plus maintenance and replacement protocols—all of which have costs associated. Factors at play include:

Technology lifespan and degradation rate. An energy storage system’s service life is determined by technology and cycles. All energy storage systems deteriorate over time, making them less efficient at storing and discharging energy. The same goes for generation sources. From solar to wind to flow batteries to lithium-ion, the more the components are used, the shorter the lifespan and the sooner the need for repair, replacement or augmentation.

Maintenance costs. Solar panels, wind turbines, battery systems, transmission lines, and power equipment all have to be maintained. The more they’re used, the more often components need to be serviced or replaced.

Long-Duration Doesn’t Always Mean Lower LCOS

The latest buzzy term in the energy space is “long-duration energy storage,” or LDES for short. While there’s no single definition of what the term means, the term has generally come to describe a non-lithium storage technology that can provide energy for anywhere from 8 to 160 hours at a lower installed cost per MW than lithium-ion batteries or a standard natural gas turbine.

LDES isn’t confined to battery storage; non-battery technologies include compressed air, latent heat, flywheels, and more. In fact, pumped hydro currently accounts for the vast majority of all LDES capacity in the US, and will likely remain in that position for an extended time. Battery technologies being positioned for LDES use include flow batteries, zinc-based chemistries, metal air, nickel hydrogen, and more.

These technologies all work well and are generally safer than lithium-ion batteries, but they come with trade-offs. Many have high up-front costs and must be amortized over 30–40-year periods to be cost competitive. Some have very low energy densities, requiring significant amounts of land for installations above a few megawatt hours. Some are rate-limited and can’t discharge as quickly as needed for specific applications. Some have very restricted siting requirements. And maybe most importantly, many have RTEs below 60%, with a few at 40% or lower.

So, what does this all mean? The race is on to build a better storage system, and with no universal standard for calculating LCOS, every vendor is using a model that plays to the strength of their own technology. If you’re investigating a new storage technology, be sure to ask a few questions when LCOS numbers come up, such as:

How many years are they calculating when it comes to system life? Lithium-ion batteries usually have to be augmented or replaced somewhere between 10 and 15 years of use; vendors with low densities or high installed costs may calculate over 30–40 years to lower their LCOS while factoring in two or more replacement cycles for lithium-ion.

What are they using for the cost of electricity to charge the system, and how does that compare with your actual costs? Even if you’re only planning to charge the system during periods you’d normally be curtailing renewables, remember that there’s still a cost to running those systems. A system with a low RTE may end up having a much higher LCOS even when you’re paying very little for electricity.

Are they including the cost of land in their calculations? If you’re installing a storage facility in a rural area where land is cheap, this may not matter so much. But if you need to place storage in or near a high-cost-of-living area, cost of land (and availability) could be one of your primary concerns and should definitely play a role in the LCOS calculation.

Are they including installation tax credits (ITCs) or production tax credits (PTCs) in their calculations? If so, be sure that the numbers are correct for your projects, and that the same are being applied to any other technologies you’re evaluating.

— Mukesh Chatter is the CEO of Alsym Energy , a technology company developing a low-cost, high-performance rechargeable battery chemistry that is free of lithium and cobalt.

SHARE this article

how to calculate battery storage round trip

How to Calculate Battery Storage Round Trip

Understanding Battery Storage Round Trip

The formula for calculating round trip efficiency.

Example Calculation

Factors impacting round trip efficiency, importance of round trip efficiency calculation.

In conclusion, calculating battery storage round trip efficiency is essential for evaluating the performance and cost-effectiveness of battery storage systems. By using the appropriate formula and considering the various factors that impact round trip efficiency, you can make informed decisions about the selection and optimization of battery storage systems.

Leave a Comment Cancel Reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

Notify me via e-mail if anyone answers my comment.

WhatsApp us

- Project Finance

- Battery Storage

- Diesel Generators

- MWM Gas Engines

- MWM TCG 3016

- MWM TCG 3020

- MWM TCG 2020

- MWM TCG 2032

- Battery Energy Storage

- Cogeneration (CHP)

- Electricity Generation

- Energy Resilience

- Hybrid Power Solutions

- Quadgeneration

- Trigeneration (CCHP)

- Project Design, Engineering & Build

- Project Management

- Power Plant Commissioning

- Containerised Power Plant

- Energy Centres

- Existing buildings or boiler house

- Power Island

- Agriculture

- Commercial Buildings

- Data Centres

- District Heating

- Food and Drink Manufacturing

- Glasshouses

- Industrial and Manufacturing

- Peaking Plants

- Pharmaceuticals

- Sewage and Waste Treatment

- Case Studies

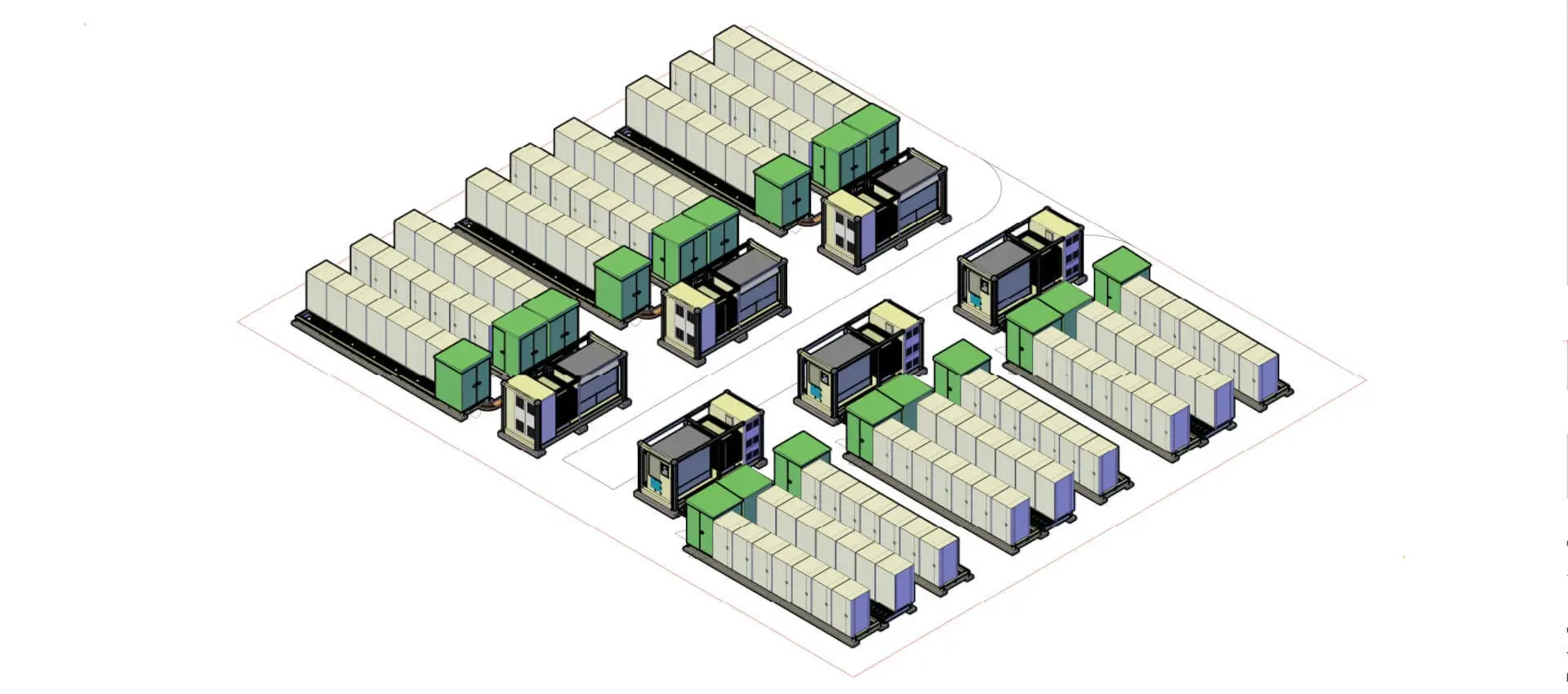

Battery Energy Storage System (BESS)

What is a battery energy storage system.

- How does BESS work?

Advantages of battery energy storage systems

- Battery energy storage system components

Principal BESS characteristics

- Types of Battery Chemistry

- Battery Energy Storage Applications

- BESS revenue sources

- Why is energy storage needed?

- What are the alternatives to BESS on energy storage?

A battery energy storage system (BESS) captures energy from renewable and non-renewable sources and stores it in rechargeable batteries (storage devices) for later use. A battery is a Direct Current (DC) device and when needed, the electrochemical energy is discharged from the battery to meet electrical demand to reduce any imbalance between energy demand and energy generation. The increase in renewable energy sources and drive to achieve net zero carbon make BESS an essential technology for commercial and industrial organisations. By adopting BESS, it can provide a vital pathway in the transition to green energy and accelerate your journey towards net zero.

How does a battery storage system work?

A BESS collects energy from renewable energy sources, such as wind and or solar panels or from the electricity network and stores the energy using battery storage technology. The batteries discharge to release energy when necessary, such as during peak demands, power outages, or grid balancing. In addition to the batteries, BESS requires additional components that allow the system to be connected to an electrical network. A bidirectional inverter or power conversion system (PCS) is the main device that converts power between the DC battery terminals and the AC line voltage and allows for power to flow both ways to charge and discharge the battery. The other primary element of a BESS is an energy management system (EMS) to coordinate the control and operation of all components in the system.

BESS Power and Energy Ratings

For a battery energy storage system to be intelligently designed, both power in megawatt (MW) or kilowatt (kW) and energy in megawatt-hour (MWh) or kilowatt-hour (kWh) ratings need to be specified. The power-to-energy ratio is normally higher in situations where a large amount of energy is required to be discharged within a short time period such as within frequency regulation applications. For pricing purposes, however, the quoted measure is usually the energy rating.

What is the Battery C‐Rate?

A battery’s C rating is the rate at which a battery can be fully charged or discharged. For example, charging at a C-rate of 1C means that the battery is charged from 0 - 100% or discharged from 100 - 0% in one hour. A C-rate higher than 1C means a faster charge or discharge, for example, a 2C rate is twice as fast (30 minutes to full charge or discharge). Likewise, a lower C-rate means a slower charge or discharge, as an example, a C-rate of 0.25 would mean a 4-hour charge or discharge. The formula is: T = Time Cr = C-Rate T = 1 / Cr (to view in hours), or T = 60 min / Cr (to view in minutes). For example:

Battery storage systems have several advantages when paired with renewable energy and non-renewable forms of generation. Solar and wind can be unpredictable, so battery storage systems are a key component in steadying energy flow by providing a steady supply whenever required, irrespective of weather conditions. Additionally, BESS can protect users from potential supply interruptions that could threaten the energy supply. Here are some of the benefits of battery storage systems:

Environmental

Installing a battery energy storage system powered by renewable energy generation technologies helps reduce carbon emissions from fossil fuels and contributes to the net zero pathways in combatting the effects of global warming.

Reduce energy costs

BESS allows consumers to store low-cost solar energy and discharge it when the cost of electricity is expensive. In doing so, it allows businesses to avoid higher tariff charges, reduce operational costs and save on their electricity bills.

Reduce grid dependency

Battery storage systems guarantee a continuous energy supply, even at times when the network is unstable due to peaks in demand or extreme weather events.

“Always on” supply

The sun is not always “on.” A battery storage system works round the clock and therefore compensates for any fluctuations in solar energy supply by storing any excess energy and maximise renewable energy generation.

Enhanced Resilience

A full battery energy storage system can provide backup power in the event of an outage, guaranteeing business continuity.

Co-location of Assets

Battery systems can co-locate solar photovoltaic, wind turbines, and gas generation technologies. In doing so, BESS co-location can maximise land use and improve efficiency, share infrastructure expenditure, balance generation intermittency, lower costs, and maximise the national grid and capacity.

Frequency Control

The battery energy storage system can regulate the frequency in the network by ensuring it is within an appropriate range. Discrepancies between generated and required energy can cause short-term problems, such as outages or blackouts, but BESS can quickly react and secure sub-second frequency response, stabilising the network. Additionally, it guarantees voltage stability by keeping it within established boundaries.

In summary:

- Battery storage can improve the reliability, availability, and efficiency of the power supply

- BESS solutions can accelerate decentralised power station infrastructure which can add value to commercial and utility-scale power generation models

- Battery storage has no significant restriction on the geographical locations that it can be sited in. Storage technologies such as pumped hydro and compressed air are only suitable for a limited number of places

- High energy density (resulting in reduced footprint) and fast response time (<150ms achievable)

Battery Energy Storage System Components

BESS solutions include these core components: Battery System or Battery modules – containing individual low voltage battery cells arranged in racks within either a module or container enclosure. The battery cell converts chemical energy into electrical energy. The batteries are connected in series and parallel for the required capacity. Storage enclosure - either as an outdoor module or containerised solution along with thermal management. Battery Management System (BMS) – which ensures the battery cell's safe working operation, ensuring it operates within the correct charging and discharging parameters. In doing so, the BMS monitors the battery cell's current, voltage, and temperature and estimates its state of charge (SoC) and State-of-Health (SoH) to prevent safety risks and ensure reliable operation and performance. Inverter or a Power Conversion System (PCS) – the battery cell produces direct current (DC), which the PCS converts into alternating current (AC) used for the power grid, commercial or industrial applications. Bidirectional inverters allow for the charging and discharging of the battery cell. Energy Management System (EMS) – controls and monitors the energy flow of the BESS and systems. The EMS coordinates the BMS, inverters and other components of the battery energy system by collecting and analysing data used to manage and optimise the overall system performance. Safety Systems – subject to system functionality and operating conditions, a BESS will include fire suppression, smoke detection, a temperature control system, and cooling, heating, and air conditioning systems. A dedicated monitoring and control system will ensure the safe operation of the BESS and the prevention of fire and hazardous incidents. The BESS will also be housed within a secure restricted access area and include CCTV monitoring.

Rated Power Capacity

Rated Power Capacity is the total discharge capability (usually in megawatts (MW)) or the maximum rate of discharge the BESS can achieve, starting from a fully charged state.

Rated Energy Storage

Rated Energy Storage Capacity is the total amount of stored energy in kilowatt-hours (KWh) or megawatt-hours (MWh). Capacity expressed in ampere-hours (100Ah@12V for example).

Storage Duration

The amount of time storage can discharge at its power capacity before exhausting its battery energy storage capacity. For example, a battery with 1MW of power capacity and 6MWh of usable energy capacity will have a storage duration of six hours.

Depth of Discharge (DoD)

Depth of Discharge (DoD) expresses the total amount of capacity that has been used.

Cycle life / lifetime

The amount of time or cycles a battery storage system can provide regular charging and discharge before failure or significant degradation. Cycle Life is the number of times a battery storage part can be charged and discharged before failure, often affected by Depth of Discharge (DoD), for example, one thousand cycles at a DoD of 80%.

Self-discharge

Self-discharge occurs when the battery's stored charge (or energy) is reduced through internal chemical reactions or without being discharged from performing work for a customer or the grid. Self-discharge is usually expressed as a percentage of the charge lost over a certain period. It is an essential parameter in batteries intended for longer-duration applications.

Discharge Rate

Discharge Rate (C) describes the current that a battery can deliver for a period of time, as an example, C5 is the current a battery will provide over 5 hours to reach full discharge.

State of Charge

The state of charge is usually expressed as a percentage representing the battery's present charge level and ranges from wholly discharged to fully charged. The state of charge influences a battery's ability to provide energy or ancillary services to the network at any given time. The state of Charge expresses the amount of capacity remaining.

Round-trip Efficiency

Round-trip efficiency is the ratio of energy charged to the battery to the energy discharged from the battery and is measured as a percentage. It can represent the battery system's total AC-AC or DC-DC efficiency, including losses from self-discharge and other electrical losses.

In addition to the above battery characteristics, BESS have other features that describe its performance.

The ramp rate is the rate at which the BESS may decrease or increase its power output - ramp down or up, respectively.

Response Time

The response time is when BESS must move from the idle state and start working at full power.

Types of Battery Chemistries

Lithium-ion (li-ion).

Lithium iron phosphate (LFP) and lithium nickel manganese cobalt oxide (NMC) are the two most common and popular Li-ion battery chemistries for battery energy applications. Li-ion batteries are small, lightweight and have a high capacity and energy density, requiring minimal maintenance and provide a long lifespan. Lithium-ion batteries can also be rapidly charged and have a low self-discharge rate. The disadvantages of this battery technology include excessive cost, inflammability, intolerance to extreme temperatures, overcharge, and over-discharge.

Lead-Acid (PbA)

Lead-Acid batteries are well-proven within the automotive industry and behind-the-meter grid and UPS applications. PbA batteries are widely available, low cost, widely recyclable, and can perform effectively at both hot and cold temperatures. However, due to advances in Li-ion battery technology, lead-acid batteries have a low energy density and are slow to charge.

Sodium-Sulphur (Na-S)

A sodium-sulphur battery is a molten salt-based device. Na-S batteries have several advantages, including high energy and power density, a long lifespan, and reliable operation under extreme 300 to 350 degrees Celsius temperatures. However, this battery technology is primarily suited to large-scale stationary grid storage applications due to high operating temperatures and corrosion sensitivity. Sodium is also a dangerous component because it is highly flammable and potentially explosive.

Flow Batteries

Flow batteries store energy in liquid electrolyte solutions, unlike traditional rechargeable battery solid electrode material. The vanadium redox battery (VRB) is the most prevalent flow battery type and is suitable for longer durations of up to 8 hours or where an extended lifetime is required. Despite their low energy capacity and charge/discharge rate, flow batteries respond quickly and reduce fire risk due to the non-flammable electrolytes used.

Zinc Bromine, cerium-zinc

A zinc-bromine battery is a rechargeable battery that uses the reaction between bromine and zinc metal to produce an electric current with an electrolyte composed of an aqueous solution of zinc bromide. The zinc-bromine battery was developed as an alternative to lithium-ion batteries for stationary power applications from grid-scale to domestic scale. The water-based electrolyte in Zinc-bromine batteries makes the battery system less prone to fire and overheating than lithium-ion batteries.

BESS Applications

Battery energy storage can be beneficial for several reasons due to the flexibility of co-locating with other renewable energy sources or non-renewable sources. Battery energy storage also requires a relatively small footprint and is not constrained by geographical location. Let’s consider the below applications and the challenges battery energy storage can solve.

Peak Shaving / Load Management (Energy Demand Management)

A battery energy storage system can balance loads between on-peak and off-peak periods. The electricity demand fluctuates depending on the day of the week, time of day, and seasonality. As such, when there is peak electrical demand, prices are at their most expensive. Alternatively, the power price is at the standard rate when demand is low during off-peak periods. Peak shaving allows users with battery energy storage systems the assets to store power during off-peak periods and discharge during peak times to reduce electricity costs.

Energy Time Shifting / Arbitrage

Energy time shifting or arbitrage allows users with BESS solutions to store their purchased power during off-peak times to use on-site when the imported power price is high. Alternatively, users can trade their stored electricity via the flexibility markets (Energy Markets, Ancillary Services, and Capacity Market) for income generation.

Battery energy storage can supply fast response backup power in the event of a mains failure to ensure infrastructure is operational and downtime is minimal. Using these battery energy storage systems alongside power generation technologies such as gas-fired Combined Heat and Power (CHP) , standby diesel generation , and UPS systems will provide increased resilience mitigating a potential loss of operational costs, whilst protecting your brand.

Frequency Response

A BESS has a frequency response which allows it to provide active power output when there is a change in the electrical grid's frequency. A deviation from the nominal frequency indicates a mismatch between power supply and demand, which can destabilise the grid, causing outages or blackouts. To restore balance quickly, the BESS can adjust its active power output by reacting to deliver sub-second frequency response to stablise and balance supply and demand within the network. The growing share of renewable generation and decentralised power plants connected to the network, means battery storage will continue to play a critical role in our energy transition.

Grid Connected

In Front-of-the-Meter (FtM) applications battery storage systems are typically referred to as utility or grid-scale battery storage and can be connected to transmission or distribution networks to reduce congestion management whilst also controlling voltage and providing reserve and ancillary services. A BESS can also support power generation assets.

Commercial and Industrial

BESS are typically Behind-the-Meter (BtM), and applications include avoiding electricity network charges, benefiting from tariff differences, delivering value-added balancing services, or enhancing on-site resilience and energy consumption when paired with on-site solar PV, thus saving money and optimising the sustainability benefits.

Co-location

BESS can be paired with other renewable and non-renewable technologies to form a hybrid power solution . For example, these hybrid systems can enhance the performance of new and existing gas engine installations. Combining a battery storage system with gas generation and solar power will go a long way to making cheaper, cleaner and more reliable power more accessible.

What are the sources of BESS revenues?

BESS projects can be attractive by obtaining ‘stacked’ revenue streams. These include:

Capacity Markets

Participants may earn revenue for entering into commitments under a statutory contract called a ‘Capacity Agreement’ with the Government. These Capacity Agreements provide a backup electricity supply to meet peak demand during system stress. The agreements may have a duration of up to 15 years.

Offtake Agreements

These agreements are with the consumers for a negotiated price. The contracts are known as Power Purchase Agreements or PPA. PPAs may have a duration of up to 15 years.

Dynamic Frequency Response

Dynamic Frequency Response provides an extremely valuable source of income. However, contracts with the National Grid typically have two years. Under the dynamic frequency response contracts, the operator responds to fluctuations in demand on the network by reducing or increasing its energy consumption. This is organised through the Dynamic Containment Service.

Energy Arbitrage

Users with BESS assets can optimise their energy usage to lower costs, improve sustainability or reduce costs. Electricity can be purchased and stored when prices are cheap and discharged during peak times to offset energy costs.

DS3 Programme

The main driver for battery storage in Ireland is the DS3 (Delivering a Secure Sustainable Electricity System) programme, which was brought in to enable Ireland to meet its 2020 renewable energy targets and to manage the increased amount of renewable generation connected to the grid.

The DS3 programme allows the system operator to procure ancillary services, including frequency response and reserve services; the sub-second response needed means that batteries are well placed to provide these services.

Why is Energy Storage needed?

Most energy systems have a varying demand with some short-term but significant peak power requirements, which results in a capacity requirement which might only be used for a fraction of the time. Energy storage enables energy to be saved for later use.

Energy storage creates capabilities and efficiencies low cost energy for the electric grid and assists in mitigating climate change.

Renewable energies are intermittent in nature, i.e., their capacities to produce energy vary with time. Energy storage from renewable energies can avoid any curtailment of renewable energies during favourable weather conditions when excess wind or solar energy gets generated.

The UK government estimates that technologies like batteries will form part of the UK’s smarter electricity grid, heat and transport technologies, supporting the integration of more low-carbon power, could save the UK energy system up to £40 billion by 2050 .

What are alternatives to BESS on energy storage?

Aside from battery energy storage systems, other energy storage technologies include:

Pumped Hydro

During periods of low electricity demand, surplus generation is used to pump water from a low-elevation reservoir up to a high-level elevation. When water is released from the high-level elevation, it flows down through a turbine to generate electricity to meet peak demand.

Compressed Air

Electricity is used to compress ambient air, which is stored under pressure in underground caverns or containers. When electricity demand is high, the pressurised air is heated and released into an expansion turbine generator for power production.

It is a way by which mechanical energy may be stored in the form of potential or kinetic energy. Electric motors accelerate a flywheel at high speeds through which the energy is stored as kinetic rotational energy. When there is an electricity demand, the spinning force of the flywheel is connected to a generator to produce power.

Thermal Energy

Electricity may produce thermal energy, which can be stored until needed. For example, electricity can be used to make chilled water during low demand and later used for cooling during peak electricity consumption. The UK's gas system distributes about twice as much energy as electricity, and this energy is used for heating. Heating demands vary with season and time of day, and thermal energy storage can load shift and smooth demand on the plant. Move heat from the summer to the winter.

Contact us about our BESS solutions

Talk To One Of Our Battery Energy Storage Specialists

Are you looking to deploy Battery Energy Storage Systems? We are a BESS turnkey EPC contractor and systems integrator of advanced global Tier 1 battery and inverter technologies to provide an industry-leading battery energy storage solution that is scalable and delivers guaranteed performance.

- Applications

- Industrial Manufacturing

- Terms of Use

- Privacy Policy and Cookies

- Modern Slavery Policy

Thunder Said Energy

the research consultancy for energy technologies

Round Trip Battery Efficiencies

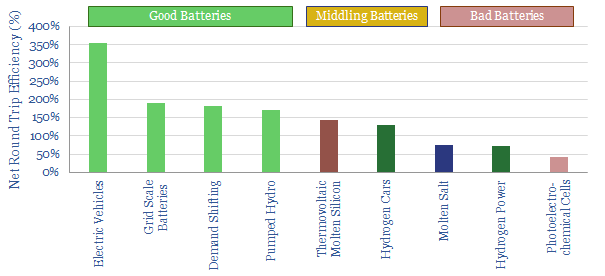

This data-file derives the ‘net round trip efficiency’ of nine different battery solutions for storing energy. Rough costs are also estimated.

Net round trip efficiency is calculated as the energy efficiency of the battery (kWh recovered per kWh fed in) divided by the energy efficiency of the displaced energy source.

We see great potential in “good batteries” , for example, electrification of the vehicle fleet, which can achieve c3.5x uplifts in efficiency. We see less potential in “bad batteries”, for example, backing up the grid with hydrogen, which reduces total system efficiency by c35%.

Privacy Overview

- ExxonMobil to supply U.S. produced Lithium to SK On

- Castrol to invest USD 50M in Gogoro’s battery swapping ecosystem

- ElectroRide and Battery Smart to establish battery swapping at 2,500 locations across India

- Amara Raja to license LFP cell technology from Gotion-InoBat-Batteries

- Musashi starts production of EV e-2W e-axles in India

Understanding Battery Energy Storage System (BESS) | Part 2 – Advanced

The first part of this series covers the basics and constituents of BESS in the Dec 2022 issue of EVreporter magazine. In continuation, part 2 explores BESS in-depth and discusses BESS design and technical parameters in greater detail.

BESS Design

The market is shifting towards the 1500V DC system of BESS. Below is a possible design that can be used in such a high-voltage system.

- 44 cells of 280Ah, 3.2V connected in series in one module

280Ah, 44*3.2V = 280Ah, 140.8V i.e. 39.424 kWh/module

44S1P cell configuration in the module

- 9 individual modules connected in series in one rack

280Ah, 9*140.8V = 280Ah, 1267.2V i.e. 354.816 kWh/rack

396S1P cell configuration in the rack

- 9 racks connected in parallel in one 20 feet container

9*280Ah, 1267.2V = 2520Ah, 1267.2V i.e. 3.19MWh

396P9P cell configuration for the entire 20 feet container

Inputs for designing BESS

- 280Ah, 3.2V LFP Prismatic cell is very popularly used in BESS, and the same is considered for the above design.

- 44 number of cells connected in series in a module can also be increased to 48 and 52 series. The number of modules per rack can be 8 or 9, depending on the height of the module and the container selected.

- The number of racks in a 20 feet container can be 9 or 10.

The below image shows a line diagram of a popular type of BESS + Solar system:

Battery Thermal Management System (BTMS) – BESS operating without thermal management in high temperatures can lead to lower battery cycle life. On the other hand, batteries operating without thermal management in lower temperatures (sub-zero temperatures) can lead to lower output of energy from the BESS. Hence, keeping the BESS operation close to the ideal operating temperature of the battery, which is 25±2°C in the case of Lithium-ion batteries, is imperative. The temperatures sometimes vary from place to place depending on other environmental conditions such as atmospheric pressure, altitude, etc.

Duck Curve – The name duck curve is derived from the shape of the graph representing the time of the day on the x-axis and energy demand on the y-axis. In some places, due to the duck curve, solar panels are partially turned off to avoid damage to the grid . This situation typically arrives in places that are heavily dependent on Solar PV.

During the peak hours, typically sometime during the noon, the generation tends to be the highest, and if the demand is lower during the same period, a duck curve is expected.

Selection of battery type

BESS can be made up of any battery, such as Lithium-ion, lead acid, nickel-cadmium, etc. Battery selection depends on the following technical parameters:

- BESS Capacity : It is the amount of energy that the BESS can store. Using Lithium-ion battery technology, more than 3.7MWh energy can be stored in a 20 feet container. The storage capacity of the overall BESS can vary depending on the number of cells in a module connected in series, the number of modules in a rack connected in parallel and the number of racks connected in series.

- Power Rating (C rate of Charge and Discharge) : It is the capability of the BESS to charge at a certain speed and discharge at a certain speed. It is directly proportional to the power input and power output, respectively.

- Cycle life : It is defined as the total number of charge and discharge cycles that the BESS can supply during its lifetime by the time it reaches its end-of-life (EOL). Depending on the life expected from the BESS, batteries such as Lead acid batteries (low cycle life) and Lithium Iron Phosphate (LFP) batteries (high cycle life) are used.

- Depth of Discharge (DoD) : It is the percentage of energy discharged from the BESS out of the total energy storing capacity. Lower DoD can ensure higher cycle life of the BESS. Generally, the maximum DoD is set at 90% for BESS.

- Round-trip Efficiency : It is the percentage of energy delivered by the BESS during discharging when compared to the energy supplied to the BESS during charging. Flow battery technology has lower round-trip efficiency compared to Lithium-ion batteries. It means that higher energy is wasted (during charge-discharge) when flow batteries are preferred over Lithium-ion batteries.

- Usable Energy : For the above-mentioned BESS design of 3.19 MWh, energy output can be considered as 2.64 MWh at the point of common coupling (PCC). This is calculated at 90% DoD, 93% BESS efficiency, ideal auxiliary consumption, and realistically considering the conversion losses from BESS to PCS and PCS to Transformer.

- Operating Conditions : The operating temperature is key to selecting the type of battery. For example, an LFP battery would be considered in areas that experience high temperatures. In this scenario, using Lithium Nickel Manganese Cobalt Oxide (NMC) batteries would not be recommended.

About the Author

About the author – Rahul Bollini is a Lithium-ion cell and battery pack R&D expert . He has industrial experience of over 7 years. Rahul can be reached at +91-7204957389 and [email protected].

This article was originally published in EVreporter Magazine Jan 2023 issue that can be accessed here .

Read: Part 3 of this series

Subscribe today for free and stay on top of latest developments in EV domain.

You May Also Like

IIT Guwahati team recommends drivetrain and battery sizing for e-2W in India

A guide to PCB materials used in EV manufacturing

Understanding the Sense-of-Touch technology for safer driving

One thought on “ understanding battery energy storage system (bess) | part 2 – advanced ”.

Pingback: Understanding Battery Energy Storage System (BESS) | Part 1 - BASICS • EVreporter

Leave a Reply Cancel reply

You must be logged in to post a comment.

Thanks, I’m not interested. Please don't ask ask again.

- Product Information

- Where to Buy

- Become a Dealer

- Contact Technical Support

HOW TO CALCULATE THE ENERGY COST OF DIFFERENT BATTERY CHEMISTRIES?

- May 5, 2021

- Fortress Power

Over 90% of newly installed energy storage worldwide are paired with Lithium batteries, even though the cost of the lithium batteries is much higher than the that of Lead Acid batteries. Why do developers, investors and utilities prefer Lithium over Lead Acid? The answer is simple, it delivers much more cycles and costs substantially less over its life span.

Our engineers have studies and tested Lithium Iron Phosphate (LFP or LiFePO4), Lithium Ion (Lithium Nickel Manganese Cobalt) and Lithium Polymer (LiPo), Flood Lead Acid, AGM and Nickel Iron batteries. We compared their round-trip efficiency, life cycles, total energy throughput and cost per kWh.

What’s Battery Energy throughout? It is the total amount of energy a battery can be expected to store and deliver over its lifetime. How to calculate this energy amount? The Energy Throughput is equal to Nominal Capacity x Round-trip Efficiency x Depth of Discharge x Battery Cycle Life . For example, A Fortress LFP-10 has a normal capacity of 10.2 kWh and an exceptional roundtrip efficiency of 98%. We guarantee 6000 cycles at 80% of Depth of Discharge (DoD). The total energy throughput you can obtain from the LFP-10 will be 47 MWH. As a contrast, a 10 kWh AGM battery can only deliver 3.5 MWH total energy, less than 1/10 of the LFP battery.

The Fortress LFP-10 is priced at $ 6,900 to a homeowner. As a result, the energy cost of the LFP-10 is around $ 0.14/kWh ($ 6900/47MWH = $ 0.14/kWh). While a 10 kWh AGM’s energy cost is $ 0.57/kWh, 3.5 times more!

Using the same method, the energy cost of Lithium Ion batteries (such as Tesla, LG Chem, Panasonic) is around $ 0.30/kWh.

If you have any questions or need any further information, please email us at [email protected] or Call us at (877) 497 6937.

Get updates delivered

Recent posts.

GreenLancer Energy & Fortress Power Partnership to Provide Solar Energy Solutions

Detroit, MI, [4/29/2024]—GreenLancer Energy, a nationwide leader in solar design and engineering services, and Fortress Power, a solar battery and inverter manufacturer, are thrilled to

Skylight Lending and Fortress Power Partner to Offer Energy Storage with Financing

Philadelphia, PA [4/24/2024]—Skylight Lending, a nationwide leader in solar system financing, and Fortress Power, an energy storage solutions provider, are thrilled to announce a collaboration

Avalon Roadshow – May 2024: Do More with Less

With the Avalon whole-home energy storage system you can do more with less. Join us for an in-person training near you to learn about the

Por Los Nuestros and Fortress Power Honored with PR Energy Island-Wide Project Award for Solar Aqueducts Project

Por Los Nuestros and Fortress Power Honored with PR Energy Island-Wide Project Award for Solar Aqueducts Project Puerto Rico – March 28, 2024 – Por

See All Blog Posts

JOIN OUR COMMUNITY

Rebates Available for

Members of the Armed Forces and Veterans!

APPLICATIONS

Quick links.

- 2010 Cabot Blvd West Suite L, Langhorne, PA 19047

- [email protected]

877-497-6937

© 2024 Fortress Power. All Rights Reserved.

- Terms of Service

- How do you describe yourself? * Homeowner Installer Distributor Other

- Enter your email address *

- Name * First Last

- Company/Organization *

- Country * United States Canada Mexico Afghanistan Albania Algeria American Samoa Andorra Angola Anguilla Antarctica Antigua and Barbuda Argentina Armenia Aruba Australia Austria Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Belgium Belize Benin Bermuda Bhutan Bolivia Bonaire, Sint Eustatius and Saba Bosnia and Herzegovina Botswana Bouvet Island Brazil British Indian Ocean Territory Brunei Darussalam Bulgaria Burkina Faso Burundi Cambodia Cameroon Cape Verde Cayman Islands Central African Republic Chad Chile China Christmas Island Cocos Islands Colombia Comoros Congo, Democratic Republic of the Congo, Republic of the Cook Islands Costa Rica Croatia Cuba Curaçao Cyprus Czech Republic Côte d'Ivoire Denmark Djibouti Dominica Dominican Republic Ecuador Egypt El Salvador Equatorial Guinea Eritrea Estonia Eswatini (Swaziland) Ethiopia Falkland Islands Faroe Islands Fiji Finland France French Guiana French Polynesia French Southern Territories Gabon Gambia Georgia Germany Ghana Gibraltar Greece Greenland Grenada Guadeloupe Guam Guatemala Guernsey Guinea Guinea-Bissau Guyana Haiti Heard and McDonald Islands Holy See Honduras Hong Kong Hungary Iceland India Indonesia Iran Iraq Ireland Isle of Man Israel Italy Jamaica Japan Jersey Jordan Kazakhstan Kenya Kiribati Kuwait Kyrgyzstan Lao People's Democratic Republic Latvia Lebanon Lesotho Liberia Libya Liechtenstein Lithuania Luxembourg Macau Macedonia Madagascar Malawi Malaysia Maldives Mali Malta Marshall Islands Martinique Mauritania Mauritius Mayotte Micronesia Moldova Monaco Mongolia Montenegro Montserrat Morocco Mozambique Myanmar Namibia Nauru Nepal Netherlands New Caledonia New Zealand Nicaragua Niger Nigeria Niue Norfolk Island North Korea Northern Mariana Islands Norway Oman Pakistan Palau Palestine, State of Panama Papua New Guinea Paraguay Peru Philippines Pitcairn Poland Portugal Puerto Rico Qatar Romania Russia Rwanda Réunion Saint Barthélemy Saint Helena Saint Kitts and Nevis Saint Lucia Saint Martin Saint Pierre and Miquelon Saint Vincent and the Grenadines Samoa San Marino Sao Tome and Principe Saudi Arabia Senegal Serbia Seychelles Sierra Leone Singapore Sint Maarten Slovakia Slovenia Solomon Islands Somalia South Africa South Georgia South Korea South Sudan Spain Sri Lanka Sudan Suriname Svalbard and Jan Mayen Islands Sweden Switzerland Syria Taiwan Tajikistan Tanzania Thailand Timor-Leste Togo Tokelau Tonga Trinidad and Tobago Tunisia Turkey Turkmenistan Turks and Caicos Islands Tuvalu US Minor Outlying Islands Uganda Ukraine United Arab Emirates United Kingdom Uruguay Uzbekistan Vanuatu Venezuela Vietnam Virgin Islands, British Virgin Islands, U.S. Wallis and Futuna Western Sahara Yemen Zambia Zimbabwe Åland Islands

- State Alabama Alaska Arizona Arkansas California Colorado Connecticut Delaware District of Columbia Florida Georgia Hawaii Idaho Illinois Indiana Iowa Kansas Kentucky Louisiana Maine Maryland Massachusetts Michigan Minnesota Mississippi Missouri Montana Nebraska Nevada New Hampshire New Jersey New Mexico New York North Carolina North Dakota Ohio Oklahoma Oregon Pennsylvania Rhode Island South Carolina South Dakota Tennessee Texas Utah Vermont Virginia Washington West Virginia Wisconsin Wyoming Armed Forces Americas Armed Forces Europe Armed Forces Pacific

- Email This field is for validation purposes and should be left unchanged.

ENERGY YOU CAN DEPEND ON

- Download Center

- GridTECH Connect

Calculating the True Cost of Energy Storage